Introduction

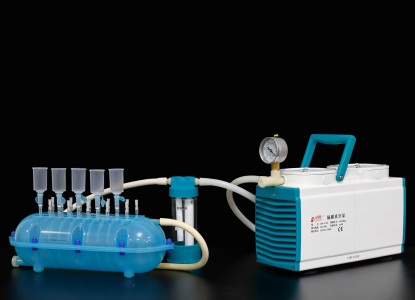

The MagVac 20 suction filtration system is a rapid extraction device specially designed for column membrane nucleic acid extraction kits.The lysate and cleaning solution are combined and cleaned through the column by negative pressure, rather than relying on centrifugal force.During suction filtration, the waste liquid generated during the column binding and cleaning is directly sucked and filtered into the waste liquid bottle. There is no need to repeatedly take the tube and discard the waste liquid, so the operation steps are simpler and the time is shorter. The MagVac 20 suction filtration system is compatible with all kinds of adsorption columns on the market.